数据记录软件 GA10 (Data Logging Software)

通过在PC上集中监控和记录任务来节省时间和精力!!

主要优势 :

- 多机型连接

可广泛对应数据采集器、记录仪、温度调节器、信号变换器、电力监视器、功率计,也可以实现Modbus仪表的数据采集。 - 简单设置

- 只需选择连接的仪器即可完成准备工作(简单设置模式)。

- 轻松配置趋势波形的自动打印(报表/打印功能可选)。

- 高可靠性

- 具备通信断开时自动重新连接、停电时数据文件及时保护等功能。

- 数据补救功能( 回填功能):仅当使用GM/GX/GP/DX/CX/MV 本体记录且时间戳设定为仪表时刻优先时可用。

- 支持服务器操作系统 ServerOS

- 直观的画面

- 多种显示画面

- 实时监控

- 丰富的功能

- 报警音

- 通过电子邮件发送通知

- 运算通道(选件)

- 报表打印(选件)

- OPC-UA服务器(选件)

- 支持多记录标准

- 2种时间模式

- 用户权限设定

- 添加监视计算机(客户端)

- DDE服务器(通过例如Microsoft Excel等对应DDE的软件实现测量数据活用)

- 版本3现在包括直接连接到WT3000/3000E功率分析仪以及生成定制图形的能力。

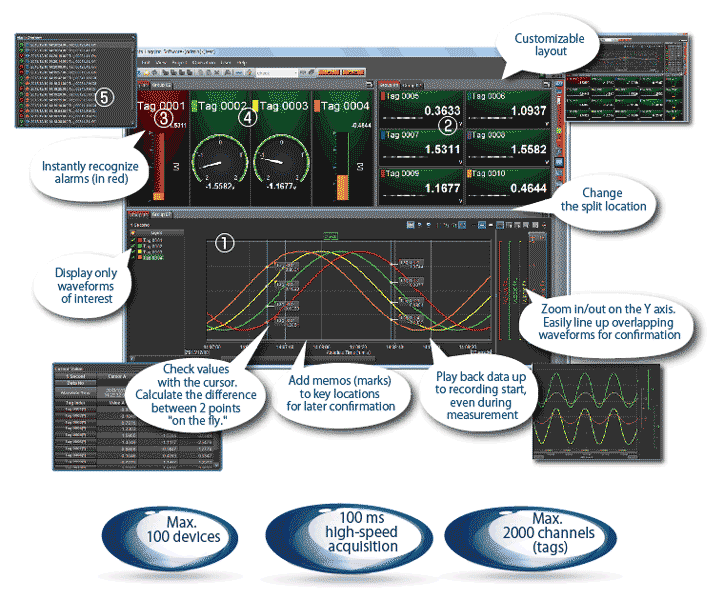

直观的画面

- 丰富的画面显示

(1) 趋势显示 (2) 数字显示 (3) 柱形仪表显示 (4) 模拟表盘显示 (5) 报警监测/ 日志 - 实时监控

多机型连接

可广泛对应数据采集器/ 记录仪/ 温度调节器/ 信号变换器/ 电力监视器/ 功率计,也可以实现Modbus 仪表的数据采集。

有关对象机型的详细信息,请参阅规格书。

兼容型号

| Products to be connected | |

|---|---|

| 记录仪 | GX10, GX20, GP10, GP20 |

| DX1000, DX1000N, DX2000, DX1000T, DX2000T, FX1000 | |

| MV1000, MV2000 | |

| CX1000, CX2000 | |

| µR10000, µR20000 | |

| 数据记录器 | DA100, DR130, DR230, DR240 |

| MX100, MW100 | |

| 控制仪表设备 | 下述机型作为Modbus仪表连接:UT75A, UT52A, UT55A, UT35A, UT32A, UP55A, UP35A, UM33A |

| 功率监控器 | PR300 (作为Modbus仪表连接) |

| 信号调节器 | 下述机型作为Modbus仪表连接:VJU7, VJS7, VJA7, VJH7, VJP8, VJQ7, VJQ8, VJX7, MVHK, MVRK, MVTK |

| 功率计 | WT300, WT500, WT1800 |

| Modbus 仪表 | 支持Modbus通信的仪表 |

| 软件 |

DAQLOGGER/ DAQ32Plus / MXLOGGER |

*免费提供连接用软件 GateWT for GA10

简单设置

采集的设定

只需选择连接的仪器即可完成准备工作。如果是采集器/ 记录仪可以自动反映标记名。很容易实现多通道的数据采集。细微的配置变更也是可能的。

自动打印的设定(NEW!)

曲线波形打印输出的自动化。可以选择设定打印内容,对象通道,打印机等。也可自定义模板后,创建Excel 或PDF 文件。(报表 / 打印功能选项)

高可靠性

- 具备通信断开时自动重新连接、停电时数据文件及时保护等功能。

- 数据补救功能( 回填功能)

*仅当使用GM/GX/GP/DX/CX/MV 本体记录且时间戳设定为仪表时刻优先时可用。

丰富的功能

- 报警音

发生报警时,驱动PC蜂鸣音。 - 发送电子邮件

- 根据采集情况发送邮件

- 可以设定多个发送条件或发送内容

- 支持SMTP认证、POP Before SMTP认证

- 运算通道(选件)

- 测量数据的实时运算

- 对应包括四则运算的各种运算

- 可报警设定

- 报表打印(选件)

- 曲线、时报/日报等数据的自动打印

- 可自定义模板、创建Excel或PDF文件

- OPC-UA服务器(选件)

- 对应安全性较高的OPC-UA通信

- 通过对应的SCADA或数据库等实现测量数据的活用

- 支持多记录标准

实现不同时间的多个数据采集 - 2种时间模式

- 可以指定PC时刻或仪表时刻作为时间戳

- 确保与仪表本体文件的一致性

- 用户权限设定

可以设置4级权限:所有者/管理者/操作者/监测者 - 添加监视计算机(客户端)(可选)

可以使用多台计算机进行监测或共享数据 - DDE服务器

通过例如Microsoft Excel等对应DDE的软件实现测量数据活用

厂区内的数据监测

现从办公区到现场的异地远程数据监控,通过追加客户端,多台终端共享数据。

多台试验设备的数据记录

将试验设备的数据保存到计算机上,可以按设备在不同时间进行记录。

| OS | Windows XP, Windows Vista, Windows 7, Windows 8, Windows Server 2008 R2, Windows Server 2012 |

| CPU | 推荐Pentium 4, 3.2 GHz 以上, 64bit OS |

| 内存 | 2 GB 以上 |

| 硬盘 | 200 MB 或以上的可用空间 |

| 显示器 | 1024 x 768像素或以上,65,536 色 或以上 |

| 通信接口 | 对应OS的RS-232 端口,Ethernet端口,USD端口 RS-422/485通信时请使用转换器(推荐使用横河电机的ML2)。 |

数据记录软件基本序列号

增加通道时

增设监视计算机(客户端)时

构成示例

操作手册

- WX1 GateWT User's Manual (859 KB)

- 数据记录软件GA10/GA10CL/GA10UP使用说明书 (45.0 MB)

规格说明

- Boiler Data Logging Software (885 KB)

- Before Using GateWT for GA10 (258 KB)

- GA10 and Associated Products (519 KB)

- GA10 Data Logging Software Setup Guide (8.1 MB)

- GA10 Data Logging Software Product Introduction Guide (2.8 MB)

- GA10 Data Logging Software (1.7 MB)

软件

返回顶部

微信扫一扫

获得更多专业服务

获得更多专业服务