Getting to next generation multi-motor analysis

December 11, 2019

As powertrains, charging systems, infotainment and safety systems grow more sophisticated in the era of the connected car, hybrid and electric vehicle development requires mechatronic analyses of unprecedented certainty and flexibility.Electric vehicles (EV) or fuel cell vehicles (FCV), which are accelerating development as an environmental conservation on a global scale, are increasingly required to evaluate a plurality of motors. This calls for effective and simultaneous evaluation of these multiple motors.

More than one motor

Hybrid vehicles may have started with one electrical motor to support the combustion engine, but modern electric cars use two electric motors and in the future may feature an electrical hub motor in each of the four wheels. Having worked for years with with leading automotive companies, it was clear to our engineering team that this would not only require more electrical inputs but also more mechanical inputs to measure the drive train efficiency. This is why the modular design of the WT5000 accomodates not only upto seven swappable input modules but alos the ability to measure up to four motors simultaneously. The WT5000 is the first among a new generation of measurement instruments from Yokogawa. Released in September 2018, it features an industry first multi motor evaluation module to support the increasing need for simultaneous and synchronized mechatronic measurements.

Mechatronic measurements

Powertrain development involves taking measurements form multiple phases for battery, inverter and motor to evaluate the likes of torque, rotation speed and direction, and slip. Multiple six-phase motor systems need to be evaluated and there also needs to be harmonic evaluation of inverter signals due to superimposition from switching circuits.The WT5000’s accuracy and the ability to evaluate four motors simultaneously could be important here along with its wide input range, sensor compatibility and the seven swappable input modules slots. The unit can carry out two harmonic measurement functions simultaneously, each at up the 500th order and up to 300kHz fundamental waveform. This makes it possible to measure the carrier frequency component from the rotational speed of the motor in the inverter drive and to check the influence of the carrier frequency on the motor drive.

Multi Motor evaluation

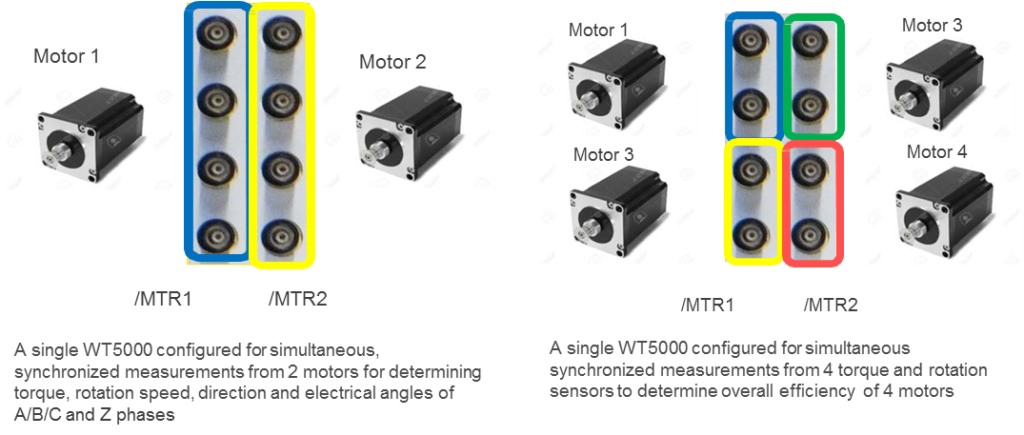

Using the analog or pulse outputs of torque sensors or pulse inputs of rotation sensors, the motor modules (MTR1 and /MTR2) on the WT5000 allows engineers to evaluate up to four motors simultaneously on a single unit. A simple setting in the motor configuration menu, allows a single WT5000 to take synchronous measurements from up to 4 torque and rotation sensors enabling users to determine the overall efficiency from 4 wheel driven vehicles. Alternatively the 4 input channels in each motor module may be used to evaluate the A/B/C and Z phases of two motors simultaneously. Some of the key parameters that can be measured using the multiple mode of operation on the motor evaluation function are :

Measurement Parameters include

- Rotation speed & rotation direction

- Torque & Mechanical power

- Synchronous speed, Slip

- Electrical angle

- Motor efficiency

To learn more about the modular architecture, multi motor evaluation and premium accuracy, meet the next generation in precision .

WT5000 - Präzisions-Leistungsanalysator

Der Präzisions-Leistungsanalysator WT5000 definiert die neue Referenz in der Leistungsmesstechnik mit einer aktuell weltweit höchsten Grundgenauigkeit von ± (0,01 % des Messwerts + 0,02 % des Effektivwert-Messbereichs). Jedes erdenkliche Anwenderszenario wird durch die modulare Bauweise (Self-Service) sowie durch die mögliche Kaskadierung realisiert: bis zu 28 Leistungsmesskanäle plus 16 Motoreingänge gewährleisten vollumfängliche Messungen. Die neue „Digital Parallelpfad-Technologie“, wie auch die Harmonischen-Analyse (bis zur 500. Ordnung) runden den Leistungsumfang ab.

Suchen Sie mehr Informationen über unsere Mitarbeiter, Technologie oder Lösungen?

Ihr Kontakt zu uns